If your dryer makes a strange noise but not spinning, there is most likely an issue with the drive belt. A drive belt is the part that allows the drum to spin during a cycle. It fits between the motor and the drum pulley. While the drive belt is the most common cause, other causes can include issues with the idler pulley, worn dryer rollers, glides, support bearing, or a defective motor.

We have compiled a list of simple steps you can take to troubleshoot your dryer.

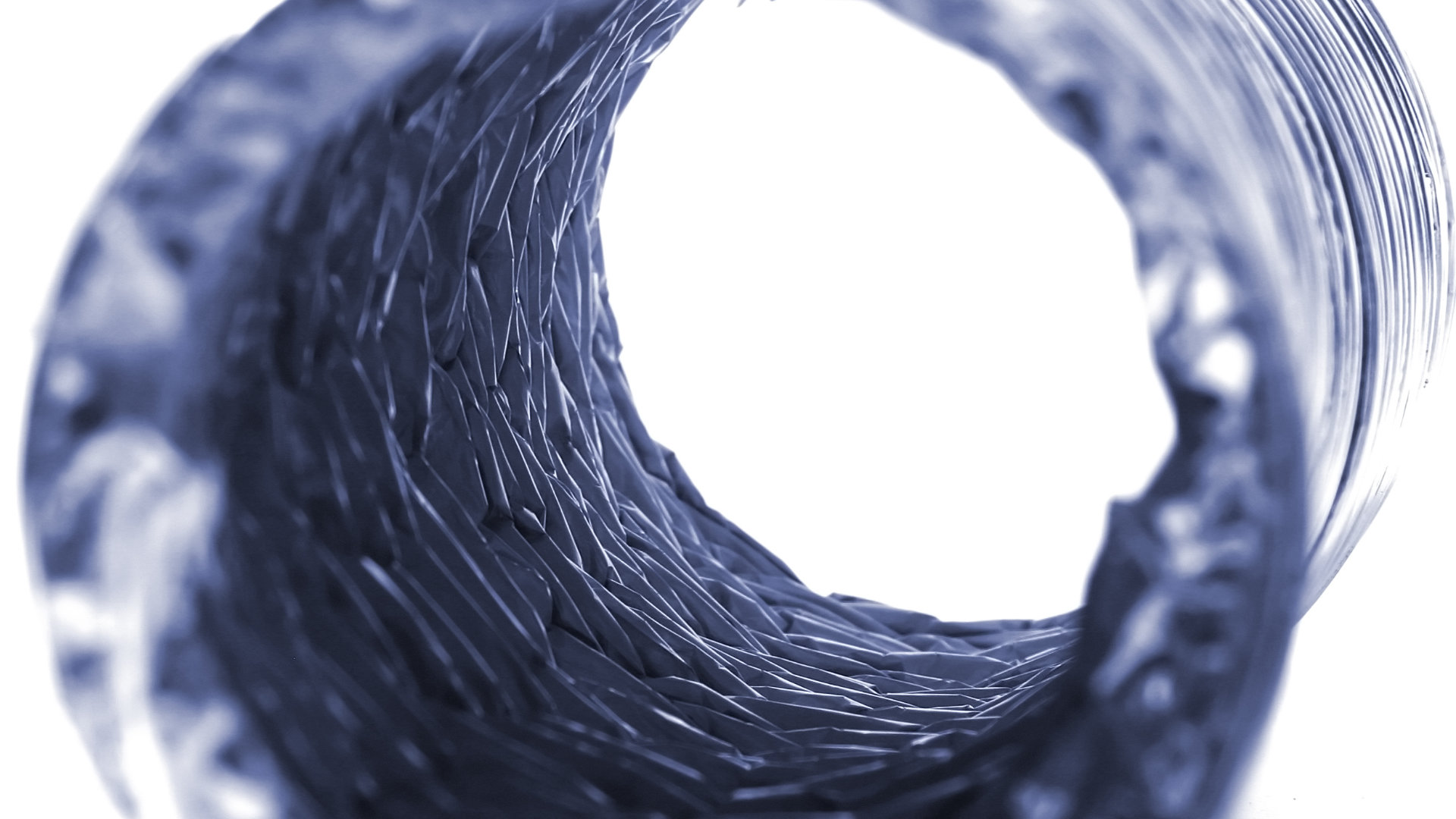

Check if the dryer belt is worn or broken

The dryer humming but not spinning is a good indication of an issue with your dryer’s drive belt. It could be damaged, worn, or broken. You can test this without removing any panels by reaching inside the dryer and trying to turn the drum manually. If the drum turns easily without any resistance, then you should look at the drive belt as it is likely defective.

Accessing the dryer

Before you can start working on your dryer, you will need to gain access. For most models, you will need to remove the front panel and often the top panel of the dryer as well. If you are unsure which panels will need to be removed to check the condition of the dryer belt, then consult your owner’s manual, which will give you model-specific instructions.

Ensure you have disconnected your dryer from its power source before starting work. You may be able to remove the top panel using a putty knife to release it, depending on the model. After the top panel is off, disconnect the door switch wiring harness and unscrew the front panel of the dryer so you can remove it.

You will need to locate the drive belt, which should be tight around the drum. Check to see if the belt is worn or broken. Unfortunately, if the belt is not in good condition, it will need to be replaced before your dryer will work. You should call a repair technician if this is the case.

Check the dryer belt is off the idler pulley

If your drive belt is in good condition, the issue may be that the belt has come off the idler pulley. You will need to visually inspect the dryer belt and pulleys to see if the belt has come off. If so, the belt will need to be put back on before your dryer will work. You should also replace any damaged pulleys.

Check if you have a damaged idler pulley

The idler pulley is important because it helps rotate the dryer drum. It does this by putting tension on the drive belt. The tension should ensure the belt does not come off. Hearing squeaking along with the humming is a common indication one or all of your bearings inside the idler pulley are worn.

Follow these simple steps to access and replace the idler pulley:

- Ensure your dryer is disconnected from the power or gas.

- Remove the relevant access panels. Consult your owner’s manual if needed.

- Locate the idler pulley at the bottom of the dryer; you may need a torch.

- Check the idler pulley for any damage or wear.

- If the idler pulley needs to be replaced, you will need to release the belt. Push the idler pulley to the right to release the tension on the belt.

- Remove the belt from the idler pulley. There may be screws to unthread before you can remove the idler pulley from your dryer.

- Replace the defective idler pulley with a new one. Make sure you have the correct pulley for your make and model.

- You will need to rethread the drive belt through the new pulley.

- Replace the access panels and reconnect the power.

- Run a test cycle to ensure it is working as it should.

Worn drum roller or axle

Your dryer drum has rollers that help it to rotate. Depending on the model, there may be two or more rollers that support the rear of the drum. Other models have two extra rollers to support the front of the drum as well.

These rollers and their axles are prone to wearing out, which results in the drum either struggling or failing to rotate. The squeaking sound combined with the humming may indicate a problem with the rollers in addition to the idler pulley.

Follow these simple steps to check your drum rollers and axles:

- Ensure your dryer is disconnected from the power or gas.

- Remove the relevant access panels. Consult your owner’s manual if needed.

- Inspect the rollers. If they are damaged, they will need to be replaced.

- If you are replacing one, it is best to replace them all.

Check the dryer motor

When a dryer has stopped mid-cycle, that often indicates a failing motor. If the motor has overheated, it can cause the dryer to shut down. A new motor can be expensive, so it is best to consult a trained technician.

If you have gone through and checked all of those components, there are a few last things you can check before you call a qualified technician.

Overloading

You should always avoid overloading your dryer with clothes. If your dryer is overloaded, air will not be able to circulate properly, and it will increase your drying time. It will also place undue stress on your machine. A heavy drum puts extra stress on the dryer’s components and can cause the drum to rotate haphazardly and vibrate. This can lead to problems if one of the components is damaged or broken. If you hear your dryer vibrating loudly, you should stop it straight away and remove some of the items inside.

Uneven Flooring Surface

If your dryer isn’t level, it will vibrate and make other noises when it is running.

Nowadays, most dryers have leveling feet, which means you can adjust them so that your dryer sits level. You can use a bubble level and sit it on top to check if your dryer is level. The bubble should be sitting in the middle of the level. If your dryer is not sitting evenly, adjust the legs so the weight is evenly distributed across all four feet.

Your Guide to Whirlpool Microwave Replacement Parts

What to Do When Your Kenmore Dryer Won’t Start

How to Resolve the LG Washer LE Error Code

Why Does My Oven Smell Like Gas? Causes and What to Do

Maytag Dryer Not Heating? Here’s How to Fix It

6 Common Reasons Your Speed Queen Dryer Isn’t Heating

8 Reasons Your Samsung Refrigerator Is Not Cooling

9 Most Reliable Washer and Dryer Brands

How to Get Ink out of Your Dryer the Easy Way

Why Is My Fridge Making Noise That Stops When the Door Is Open?

Frigidaire Refrigerator Error Code H1: Causes & Solutions

How to Clean a Dryer Vent Without Moving the Dryer

9 Reasons Your LG Refrigerator Isn’t Cooling

LG Refrigerator Not Making Ice? Here’s What To Do!